Vapor Lock

If the vapor pressure of avgas is too low, the fuel will not vaporize properly and this will cause hard starting, especially in cold weather. If the vapor pressure is too high, the fuel will "boil" in the lines of the fuel system. Fuel vapors released in the lines by this boiling have a tendency to collect in high points and cause a vapor lock. A bubble of fuel vapor in the line, because of its compressibility, resists the flow of fuel from the tank to the carburetor or to the fuel pump.

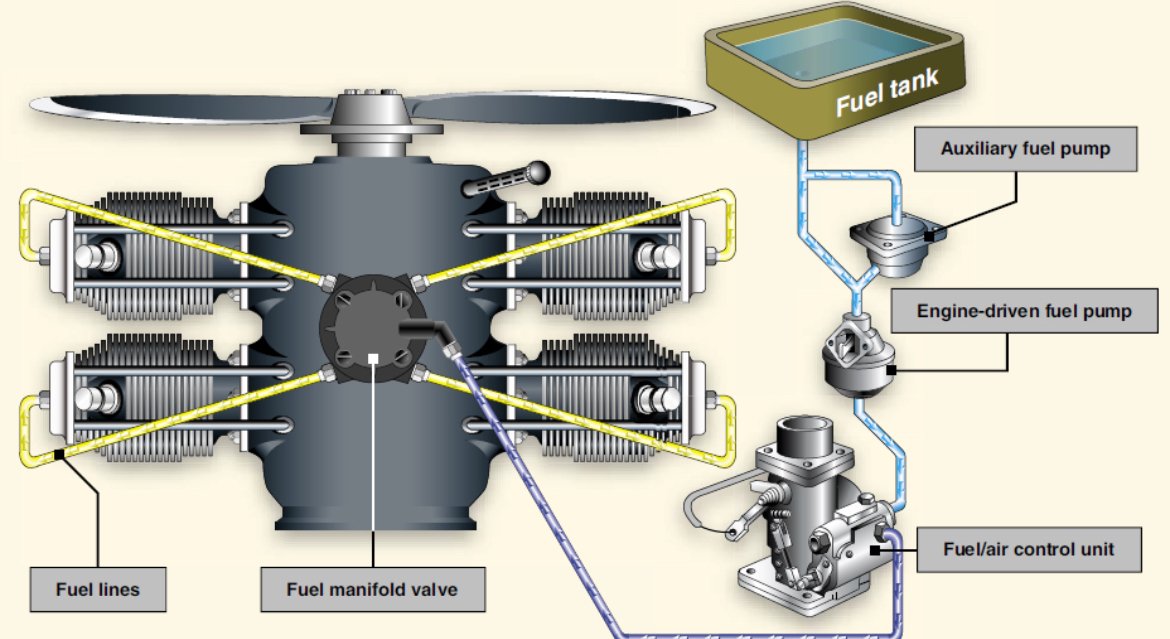

Fuel injected engines have the reputation of being difficult to start when they are hot because the high temperatures in the engine nacelle cause the fuel in the lines to vaporize. The lines from the flow divider to the nozzles will be full of vapor rather than liquid fuel. The lines must be purged of all vapors before an effective start can be made. The following procedure is recommended: The mixture control should be placed in the Idle Cut-Off position and the throttle opened wide so the boost pump can operate at full pressure. Turn the boost pump on High and allow fuel to circulate through the pump for fifteen or twenty seconds. Turn the boost pump off and place the mixture control in Full Rich. Close the throttle to the correct position for starting and engage the starter. The lines up to the fuel pump and the pump itself are now full of liquid fuel and a normal start can be made.